MEDVIC 연구실

MEchanical Design and VIbration Control

Research

- HOME

- Research

- Groove Bearing

Groove Bearing

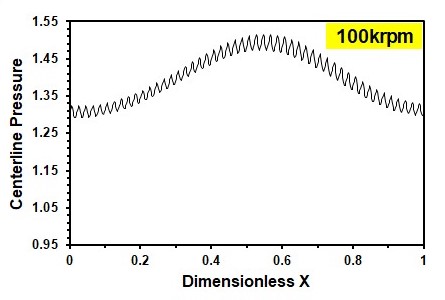

Air Herringbone Groove Bearing is a type of bearing that uses air as the lubricant to reduce friction, commonly employed in high-speed rotational equipment or precision devices where vibration control is essential. The herringbone groove pattern is designed to guide airflow evenly, providing stable support for the bearing's rotating shaft

Structure and Working Principle

Advantages

High-Speed Stability : Since it uses air instead of oil, the bearing is not sensitive to lubrication supply or temperature variations, maintaingin stability even at high speeds.

Non-Contact and Low Friction : The air film prevents direct contact, significantly reducing friction and wear, which in turn increases the equipment's durability.

Eco-Friendly : Using air as a lubricant eliminates the need for oil supply systems, reducing maintenance costs and promoting an environmentally friendly design.

Considering these design factors holistically can help achieve optimal airflow and support for air herringbone groove bearings, enhancing their performance in high-speed, low-friction applications.